We specialize in the research, development, manufacturing, and assembly of non-standard stamping parts, non-standard welding parts, individual custom parts, and non-standard assembly parts, and we can provide customized solutions based on customers’ drawings, samples, or technical requirements to meet diverse and complex project needs.

As some product information and case studies on the website are still being continuously updated and improved, if you are unable to find the detailed information you need during your browsing, please feel free to click “Contact Us” to leave a message. Our business team will get in touch with you as soon as possible and, in coordination with our professional technical staff, provide you with targeted suggestions, technical solutions, and quotation support based on your requirements.

The company has obtained certifications such as ISO 9001 and IATF 16949, and has established a strict quality control system to ensure that our products are stable, reliable, and compliant with standards. In addition, for customers who place orders that reach a certain volume, we will offer more competitive pricing while maintaining excellent product quality, creating greater value for our partners.

Customization

The experienced technical team has its own tooling workshop and can independently design and manufacture various single punch dies and progressive dies according to product drawings.

Welding is a manufacturing process that uses heat, pressure, or a combination of both to create a strong metallurgical bond between metals or other weldable materials. In the field of non-standard manufacturing, welding is not only a connection method but also a key means of achieving customized structural designs and functional requirements.

In actual production, non-standard welding is typically designed and processed based on customer-provided drawings, samples, or operating conditions. During the welding process, filler materials such as welding wire and electrodes can be flexibly selected to meet different requirements for strength, sealing, corrosion resistance, or appearance. Compared to standardized parts, non-standard welding places higher demands on process control, welding sequence, and dimensional accuracy.

Compared to mechanical connections such as bolts and riveting, welding enables more compact, stable, and integrated designs in non-standard structures, allowing the weld area to approach or even reach the performance of the base material in terms of load-bearing capacity and structural integrity. This is particularly important for complex structures, small batches, and diverse non-standard products, effectively reducing assembly steps and improving overall reliability.

The welding process is highly flexible and adaptable, capable of handling the processing needs of non-standard parts with different materials, thicknesses, and complex irregular shapes. Commonly used non-standard welding processes include MIG welding, TIG welding, laser welding, spot welding, plasma welding, and submerged arc welding, which can be selected appropriately based on product structure, precision requirements, and operating environment.

In the field of non-standard metal processing, welding is a core process for realizing personalized design, functional customization, and structural innovation. It is widely used in non-standard mechanical equipment, automated tooling, special structural components, and industrial customized components, playing a decisive role in product performance, safety, and service life.

In the field of non-standard manufacturing, welding parts are often not simply standard connectors, but rather customized components specifically designed and manufactured according to the equipment structure, operating conditions, and functional requirements. They typically serve multiple functions, including structural connection, functional implementation, and load transfer, and are core components of non-standard equipment and systems.

In non-standard applications, the primary function of welded parts is to achieve reliable connections in complex structures. Because non-standard products often exhibit inconsistent dimensions, irregular structures, or limited installation space, welding can overcome the limitations of standard parts, integrating multiple components into a single structure, ensuring overall strength and stability.

Non-standard welding parts typically need to withstand mechanical loads and structural stresses in specific directions or under specific operating conditions. Through reasonable weld seam types, welding sequences, and structural reinforcement design, welded parts not only serve a connecting function but also directly participate in load-bearing, ensuring reliable performance of equipment under long-term operation, vibration, impact, or high-load conditions.

In many non-standard equipment, welded parts also serve sealing, protection, or functional integration purposes.

Welded components also offer high design flexibility in non-standard manufacturing. Whether it's material combinations, variations in wall thickness, or complex angles and irregular structures, welding can be adjusted according to actual needs, without being limited by the dimensions and forms of standardized parts. This flexibility allows welded components to function as independent functional parts or as key structural modules in a complete machine or system.

In the field of non-standard manufacturing, Welding Parts are not merely simple welded products, but customized solutions formed by combining structural design, process experience, and usage scenarios, playing a decisive role in the performance, stability, and service life of equipment.

The application of welding parts is not limited to a single fixed product form, but is widely present in scenarios where standard parts cannot directly meet structural, functional, or installation requirements. In these applications, welding plays more of a role as a "structural implementer" and "problem solver."

Equipment frames often require custom design based on site space, load requirements, and functional layout. These structures typically have inconsistent dimensions and complex stresses, making simple assembly with standard profiles impossible.

Through non-standard welded components, profiles, plates, and reinforcements of different specifications can be integrated into a unified structure, ensuring the frame's strength and rigidity while also considering equipment installation accuracy and long-term stability.

In non-standard equipment involving media transportation, pressure, temperature, or sealing requirements, pipes, interfaces, and vessel components often require customized design based on operating conditions.

Welded components in these applications not only serve a connecting function but also directly affect sealing performance and safety. By rationally selecting welding methods and weld structures, reliable connections with complex angles, multiple interfaces, and irregular structures can be achieved, which is difficult to achieve with standard pipe fittings.

Non-standard mechanical equipment typically has specific process applications, and its structure and component assembly are highly customized.

Welding reduces the number of parts and assembly steps, improving the overall strength and reliability of the equipment.

In engineering machinery and heavy-duty equipment, many components need to withstand impact loads, vibration, and long-term fatigue conditions. These applications place extremely high demands on welding quality and structural design.

Non-standard Welding Parts, through rational material selection, weld type design, and process control, ensure that the welded structure not only meets strength requirements but also maintains stable performance under actual working conditions.

In the manufacturing of welded parts, specifications and parameters are not fixed standards, but rather the result of a comprehensive determination based on customer drawings, operating conditions, and structural functions. The selection of each parameter directly affects welding feasibility, structural strength, and the reliability of the final product.

Welding parts can be made from various metal materials, including but not limited to carbon steel, stainless steel, aluminum alloys, copper alloys, and other special alloys, depending on the product's application and operating environment.

In customized projects, material selection depends not only on strength requirements but also on corrosion resistance, weight, machinability, and weldability, ensuring that the overall performance after welding meets actual usage needs.

There is no fixed dimensional range for welded parts; all dimensions are custom-made based on customer-provided drawings, samples, or design requirements.

In actual production, dimensional accuracy not only affects the parts themselves but also directly impacts subsequent assembly and overall machine operation. During the welding process, welding deformation, heat input, and structural shrinkage are fully considered, with process allowances and controls implemented for critical dimensions.

Different wall thicknesses and cross-sectional dimensions directly affect welding methods, welding sequence, and welding parameters.

During welding, it is necessary to rationally select welding processes and heat input control methods based on differences in wall thickness to avoid welding deformation, insufficient penetration, or uneven weld performance, ensuring the stability of the structure under load and in long-term use.

Weld type (such as butt weld, fillet weld, lap weld, etc.) is not a simple selection but is designed based on the stress mode, spatial structure, and assembly requirements of the components.

Welds often simultaneously bear the functions of connection and load-bearing; therefore, the design of weld location, size, and form prioritizes structural strength and long-term reliability, not just appearance.

Welded components are typically completed using MIG, TIG, laser welding, spot welding, or a combination of multiple processes.

Process parameters such as current, voltage, welding speed, and heat input control are adjusted according to material properties and structural characteristics to ensure the consistency and stability of weld quality.

Depending on the product's operating environment and customer requirements, Welding Parts can undergo sandblasting, polishing, electroplating, spraying, or other surface treatments.

In some projects, post-weld machining, straightening, or assembly verification must also be considered to ensure that the components meet both functional and aesthetic requirements.

Welding Services are customized welding processing and technical support services provided to meet the manufacturing needs of non-standard products. Welding services are not merely "welding according to drawings," but rather a comprehensive capability encompassing structural understanding, process judgment, and process control. Each project requires a customized welding plan based on the product's application, structural characteristics, and actual operating conditions.

In actual service, welding often permeates the entire manufacturing process. By analyzing customer drawings, samples, or functional requirements, we participate in process evaluations in advance, assessing structural weldability, material compatibility, and potential deformation and stress issues, thereby selecting appropriate welding methods and process routes. This early involvement is a key characteristic that distinguishes non-standard welding services from standardized processing.

Non-standard welding services typically involve multiple material combinations, multiple structural forms, and small-batch or single-piece production, demanding a high level of experience and on-site adaptability from welding personnel. Through reasonable welding sequences, heat input control, and structural auxiliary tooling design, we can ensure weld quality while maintaining dimensional accuracy and overall structural stability.

Welding Services also include post-weld inspection, correction, and necessary quality verification to ensure that the welding results not only meet the drawing requirements but also the long-term reliability requirements of the actual use environment.

Customers often need more than just "finished welding"; they want the welding results to truly serve product functionality, structural safety, and long-term use. Professional Welding Services elevate welding from a single processing step into a complete manufacturing solution by understanding these practical needs.

Welding Services provides truly customized welding solutions. Each project undergoes a comprehensive evaluation considering product structure, material type, operating conditions, and assembly requirements, rather than simply applying fixed processes. By rationally selecting welding methods, weld types, and process parameters, the welding solution itself becomes part of the product design, rather than a reactive, afterthought.

Consistent welding quality is a core requirement in non-standard manufacturing. Because non-standard products are often produced in small batches with diverse varieties, the demands on process control and personnel experience are higher. Through standardized welding procedures, mature process experience, and focused control of key processes, we ensure that welded components from different batches and with different structures maintain consistency in strength, appearance, and reliability, reducing assembly and usage risks caused by fluctuations in welding quality.

In terms of process control, professional welding services refer to and follow relevant international or industry standards to rationally regulate the welding process. This is reflected not only in the weld formation and appearance but also in the overall reliability and safety of the welded structure, ensuring that the welded result meets the strength and service life requirements of practical applications.

A reasonable welding plan and preliminary process assessment help shorten the overall delivery time and reduce rework rates. In non-standard projects, welding problems often amplify the difficulty of subsequent processing and assembly. By identifying potential risks in advance during the welding stage, later modifications and rework can be reduced, improving overall manufacturing efficiency.

Welding services typically possess one-stop support capabilities from sample production to mass production. Whether it's single-piece prototyping, sample verification, or subsequent small-batch or continuous production, everything can be completed under the same process approach, ensuring product consistency across different stages and providing reliable support for customers' product iteration and project progress.

For example, TIG welding is suitable for high-precision and aesthetically pleasing welds, MIG welding is suitable for mass production, and laser welding is suitable for high-precision and low-heat-input applications.

Without welding, most metal products in modern manufacturing would be impossible.

Yes, the choice of welding materials directly affects the mechanical properties of the weld metal.

Selecting welding materials that match or outperform the base metal is crucial for ensuring weld quality and long-term reliability.

In the field of non-standard manufacturing and customized products, choosing to weld metal parts is not just a processing method, but a strategic investment concerning product performance, manufacturing efficiency, and long-term cost control. Compared with other connection methods, welding has significant advantages in structural realization and functional integration, bringing continuous value to business development.

Welding enables high-strength, permanent structural connections. For non-standard metal parts, products often need to withstand specific loads, vibrations, or complex operating conditions. Through proper design and implementation of welding, the connection area can approach or even reach the strength and stability level of the base material, thereby significantly improving the overall reliability of the product and reducing the risk of connection failure and subsequent maintenance costs.

Welding helps simplify structural design and reduce the number of parts. In non-standard products, over-reliance on bolts, connectors, or standard components often increases assembly complexity and potential failure points. Welding can integrate multiple parts into a single structure, reducing assembly steps, improving structural compactness, and also helping to reduce overall weight and material consumption.

From a manufacturing perspective, welding is a highly flexible and adaptable process. Whether it's irregularly shaped structures, multi-material combinations, or non-standard requirements for small batches and diverse varieties, welding can be adjusted according to drawings and actual conditions. This flexibility enables companies to quickly respond to customer customization needs, improving project execution efficiency and market competitiveness.

In terms of long-term costs, welding metal parts often results in lower overall manufacturing and maintenance costs. Although it requires higher process and technical expertise initially, stable and reliable welded structures can reduce rework, repair, and replacement frequency, saving companies significant hidden costs throughout the product lifecycle.

Mature welding capabilities also provide companies with greater freedom in product design and business expansion. When welding is no longer a constraint, design can focus more on functional implementation and performance optimization, which is crucial for non-standard manufacturing companies to continuously expand into new applications and markets.

| ISO 9001 | IATF 16949 |

|

|

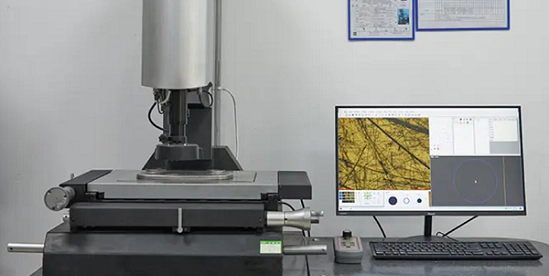

| AEH Coordinate Measuring Machine |

|

| Testing equipment | ||

|

|

|

|

|

|

| TA 1400 | BA006-N |

|

|