We specialize in the research, development, manufacturing, and assembly of non-standard stamping parts, non-standard welding parts, individual custom parts, and non-standard assembly parts, and we can provide customized solutions based on customers’ drawings, samples, or technical requirements to meet diverse and complex project needs.

As some product information and case studies on the website are still being continuously updated and improved, if you are unable to find the detailed information you need during your browsing, please feel free to click “Contact Us” to leave a message. Our business team will get in touch with you as soon as possible and, in coordination with our professional technical staff, provide you with targeted suggestions, technical solutions, and quotation support based on your requirements.

The company has obtained certifications such as ISO 9001 and IATF 16949, and has established a strict quality control system to ensure that our products are stable, reliable, and compliant with standards. In addition, for customers who place orders that reach a certain volume, we will offer more competitive pricing while maintaining excellent product quality, creating greater value for our partners.

Customization

The experienced technical team has its own tooling workshop and can independently design and manufacture various single punch dies and progressive dies according to product drawings.

Metal stamping parts are precision components produced by shaping flat metal sheets into specific forms using stamping dies and presses. Through processes such as blanking, punching, bending, forming, and deep drawing, metal stamping transforms raw metal into high-accuracy, repeatable parts that meet strict dimensional and performance requirements.

Metal stamping parts are widely used because they offer excellent consistency, high production efficiency, and cost advantages for medium- to high-volume manufacturing. From simple brackets to complex structural components, stamping parts are a foundational element in modern industrial production.

We offer fully customizable metal stamping parts based on customer drawings and application requirements.

Material options:

Carbon steel

Stainless steel (304, 316, etc.)

Aluminum alloys

Copper and brass

Surface treatments:

Zinc plating

Nickel plating

Powder coating

Anodizing

Passivation

Production processes:

Progressive stamping

Transfer stamping

Deep drawing

Compound stamping

Metal stamping, as a mature manufacturing process, has a unique cost structure compared to other manufacturing methods. Many people initially perceive it as expensive, but a deeper analysis reveals that this cost primarily stems from initial investment, not the overall long-term production expenses.

The initial investment cost does appear relatively high, especially when order volumes are small or the product design is very complex.

In other words, the mold is a one-time "fixed asset" payment, but it allows companies to quickly produce a large number of parts at a very low unit cost in subsequent production processes.

Metal stamping is best suited for medium to large-scale production.

When your order volume reaches a certain scale, the cost per product will decrease significantly, and the overall manufacturing cost will be more competitive.

Stamping parts play a vital role in modern manufacturing, offering precision, efficiency, and scalability across industries. From automotive metal stamping parts to medical, furniture, and consumer goods applications, our metal stamping solutions are designed to meet the highest standards of quality and performance. Backed by professional stamping parts services and advanced manufacturing capabilities, we are your trusted partner for precision metal components.

| ISO 9001 | IATF 16949 |

|

|

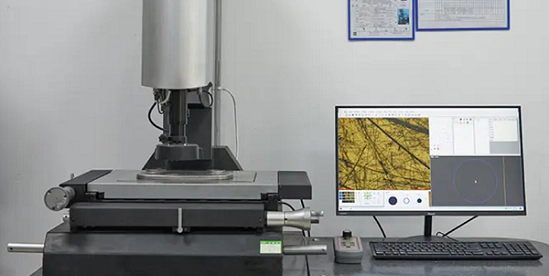

| AEH Coordinate Measuring Machine |

|

| Testing equipment | ||

|

|

|

|

|

|

| 80T-100T | 110T-350T | 500T |

|

|

|